Charlie Bacon is a Product Design Engineer, developing useful products for the past 18+ years.

E: charlie.bacon@outlook.com

T: 845.417.6938

Professional Experience

2022-Present: Product Design Engineer at Meta, New York, New York

Design and development of research and development platforms for non-invasive wearable EMG sensing systems.

Helping set direction and goals for the team, ensuring upfront alignment with stakeholders.

Navigating ambiguity in “zero-to-one” technology space, to provide impactful solutions for both fundamental science research and applied product research and development.

Scoping option space to facilitate alignment on a dominant path, with awareness of potential hedge and alternatives.

2019-2022: Manager of Mechanical Engineering at BioLite, Brooklyn, New York

Resource planning, scoping product opportunities and development timelines.

Grow Mechanical Engineering team, mentor through NPI programs, and advance test process.

Liaised external optics consultant while working with our PD team to advance a new BioLite Lantern.

Lead Mechanical Engineer on design of higher capacity power generation and storage system for BioLite.

2018-2019: Senior Product Design Engineer at Nauto, Palo Alto, California

Lead Mechanical Engineer on design of next-generation system for Nauto.

Learning from existing product, we explored new product requirements from a performance and installation perspective.

Discovered various form factors together with outside industrial design consultants Attic, in San Francisco.

Collaborated with Electrical Engineers to gain confidence in detailed architecture for kick-off with JDM.

2017-2018: Mechanical Engineering Lead, Camera Team at GoPro, San Mateo, California

Working on front-end architecture design of next generation GoPro cameras.

Cross-functional collaboration with Product Definition Managers, Industrial Design, Electrical, Optical, RF, and Audio Engineers to package minimum viable product.

Study various form factors, explore material interactions, prototype and refine.

Implement detail part design of system components, for manufacturing and assembly.

Responsible for release tooling to support alpha and prototype builds, for transition to PD team through EVT.

2014-2017: Opto-Mechanical Engineer at GoPro, San Mateo, California

Camera product development engineer packaging image engines for next generation GoPro cameras.

Interface camera mechanical and optical design team to integrate lens, image sensor, and thermal management.

Considering system requirements, pushing manufacturing capabilities, subtle advancements realize profound impacts.

Was GoPro mechanical engineering liaison to Vislink for portion of HEROCast development.

2012-2014: Design Engineer at Humanscale, New York, New York

Anthropometry awareness developing ergo conscious solutions for the office and healthcare.

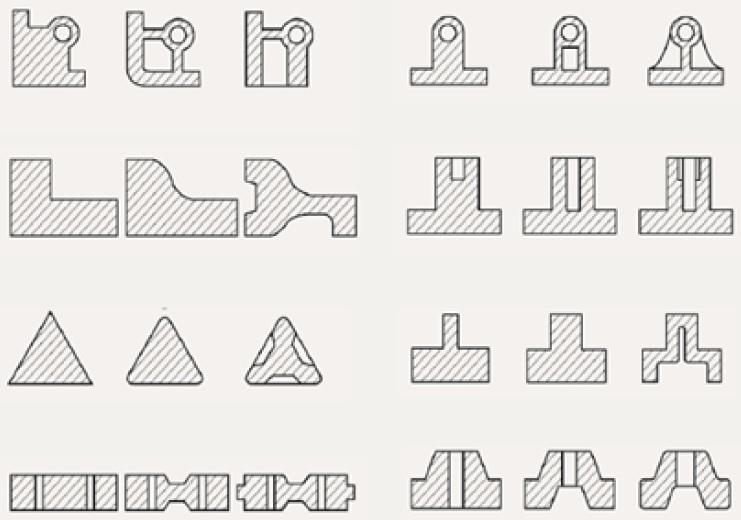

Extruded aluminum, die casting, powder metallurgy, springs, sheet metal, and plastic part design.

Center of mass attentive counterbalance mechanisms to improve dynamic adjustment experience.

Strong collaboration with industrial design to maintain aesthetic integrity when function conducts form, while always on the look out to energize form's counsel of function.

2006-2012: Mechanical Engineer at Symbol Technologies/Motorola Solutions, Holtsville, New York

Working in the Mobile Computing Division I designed for demanding environments.

Acoustical design requirements for our audio, with HAC compliancy, while IP67 rated.

Shock mounting displays for drop and tumble, various touch panel technology integration.

Optical components such as image sensors, LEDs, light pipes, lenses for imagers and laser scanners.

Material selection specific for its application; understanding properties and characteristics.

Variety of injection molding, casting, stamping sheet metal, including many secondaries experience.

Comprehensive design for heat staking and ultrasonic joining. Process optimization as well.

EMI shielding, grounding, thermal considerations and accommodations. Test validation.

Human factors evaluations. Environmental testing, while monitoring system vitals' performance.

Collaborating with industrial design to address parting lines, reveals, texture, color matching, etc. to employ a robust approach to part design for manufacturing and assembly.

Frequent travel to suppliers in China, Korea, and some Taiwanese.

Accomplishments

UTILITY PATENT:

US 8,993,153 B2

DESIGN PATENTS:

US D821,482

US D654,853 S

US D613,244 S

US D680,061 S

Brought industry first to market, with the MC95 battery's e-paper display and IP67 rating.

Cost reduced M8 dynamic adjustable arms' axle design, while improving performance.

Assisted in curtailing thermal defocus of GoPro Camera's lens systems.

Education

2019: Leadership Fundamentals Program, Center for Creative Leadership, San Diego, CA

2016: MTF in Optical and Electro-Optical Systems at SPIE, Photonics West, San Francisco, CA

2015: Opto-Mechanical Systems Engineering at SPIE, Photonics West, San Francisco, CA

2013: SolidWorks Advanced Surface Modeling with CADDEDGE, New York, NY

2010: Plastic joining overview with BRANSON ULTRASONICS, Danbury, CT

2010: Six Sigma Yellow Belt Certification, MOTOROLA UNIVERSITY, Holtsville, NY

2009: Mistake-Proof It, RESOURCE ENGINEERING, INC., www.QualityTrainingPortal.com

2008: Plastics processing and design with MOTOROLA UNIVERSITY, Holtsville, NY

2006: Pro/Engineer Wildfire training with PTC, Parsipanny, NJ

2006: BSME with a sequence in manufacturing at POLYTECHNIC UNIVERSITY, Brooklyn, NY