MC95

Once again employing our innovative monocoque housing strategy, we scaled up the environmental rigor resistance, while realizing next generation ergonomic design. The obvious narrow of the terminal around the keyboard area, is the result of our human factors group prototyping and testing many different form factors. Well sculpted, I had to ensure the integrity of the design intention for what was mostly in your hand; the battery.

I worked on delivering the first enterprise class battery to utilize e-paper technology in our industry. Display enabled battery to "report" its own status using very little energy. Once a pack had reached it's cycle life, the e-paper display would endlessly present an X, without additional power. The pack is dead, you pull it out of a drawer, and its still communicating its state of health. "Please decommission me."

E-paper display technology allowed us to not only minimize thickness, but stand up to the battery of tests this terminal was to endure. 6ft. drops to it's face, with the entire F=m*a of the terminal on it's back...at least six times. IP67 sealing. Collaborating with our industrial design team, we hid the slight increase of volume due to the display integration, in a perch for one's finger. Notice the thicker section used for the actuation button; LEDs on the thin side. Industrial design also discretely placed a secondary finger perch to further enhance grip.

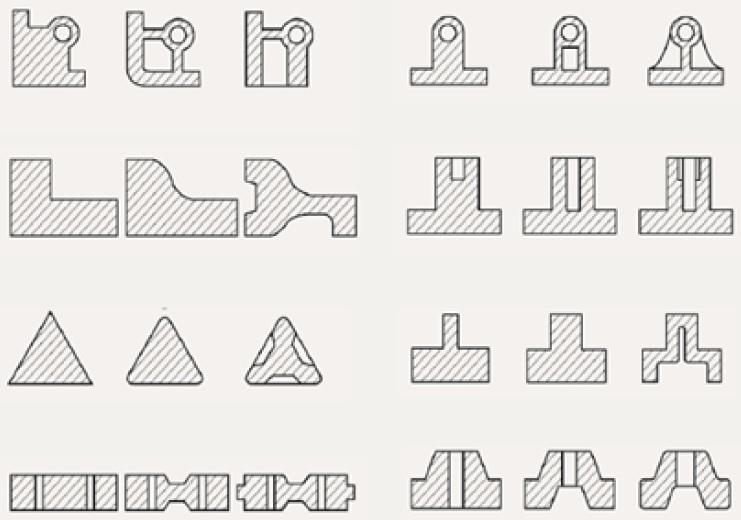

In taking on a new focused role in battery design, I was also designing custom power with I/O connectors. These were to not only maintain electrical contact through-out drop & tumble testing, but often ensure sealing too. I received a utility patent on the battery contact design for MC95, which works with various style connectors, increasing terminal and accessory design opportunities.